Precision CNC Machining for Plastic and Metal Components

High-Tolerance Machining. Human-Focused Service. Built for Your Success.

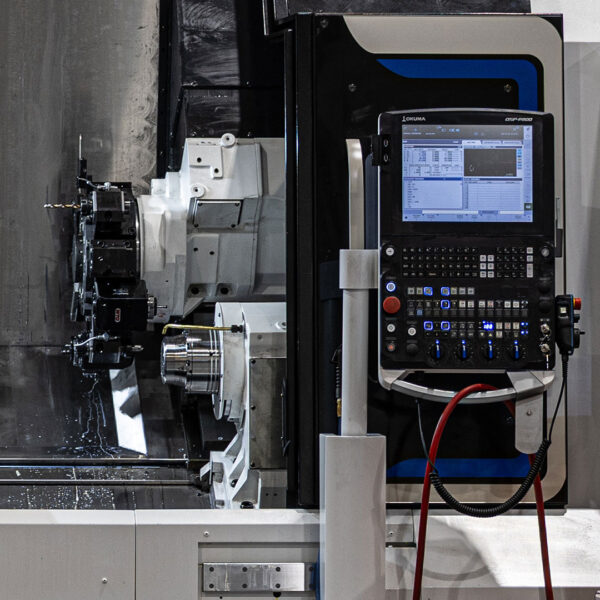

At LaFlesche, we deliver high-precision CNC Machining services for industries where every cut, hole, and finish matters, including aerospace, medical devices, defence, and marine engineering.

We work closely with technical teams, buyers, and project managers to produce components that meet tight specifications, strict regulatory standards, and demanding production schedules, all while keeping our process clear, responsive, and collaborative.

“Serious about tolerances. Serious about people. Always ISO-certified.”

Reviving a Legacy Part for Dero Industries Without Missing a Beat

In 2024, Dero Industries came to us with an urgent request: they needed a part we had machined for them back in 2005 (when LaFlesche operated under a different name.) Unfortunately, they had lost all the original drawings and documentation. The client was concerned about the time and cost of reverse engineering the worn part. Their production was on a critical timeline, and delays weren’t an option.

Our response? “Don’t worry—we’ve got it.”

Thanks to our meticulous record-keeping, we still had the original design files, CNC programs, quality procedures, and production notes stored in both physical and digital archives. We quickly coordinated with our internal team and adjusted our production schedule to create a machining window, without delaying work for our other clients. The result: a fast turnaround, a flawless part, and a very satisfied customer.

At LaFlesche, we take pride in going the extra mile because when our clients are under pressure, we treat their priorities like our own.

Reasons to Trust LaFlesche

with your CNC machining

Technical Advantages of Choosing LaFlesche

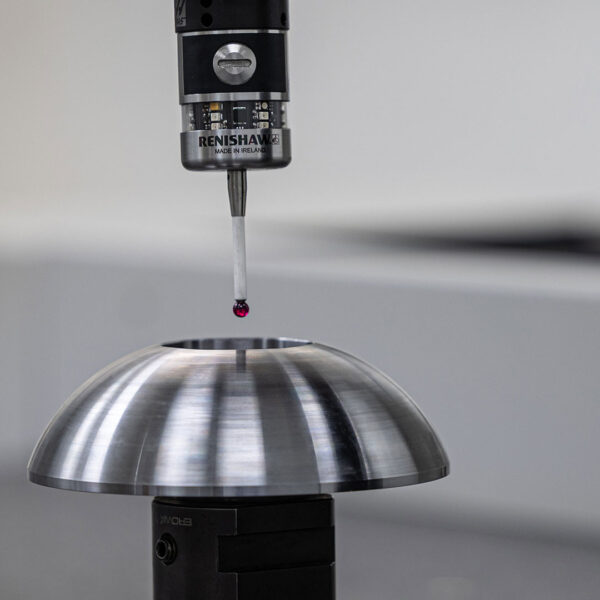

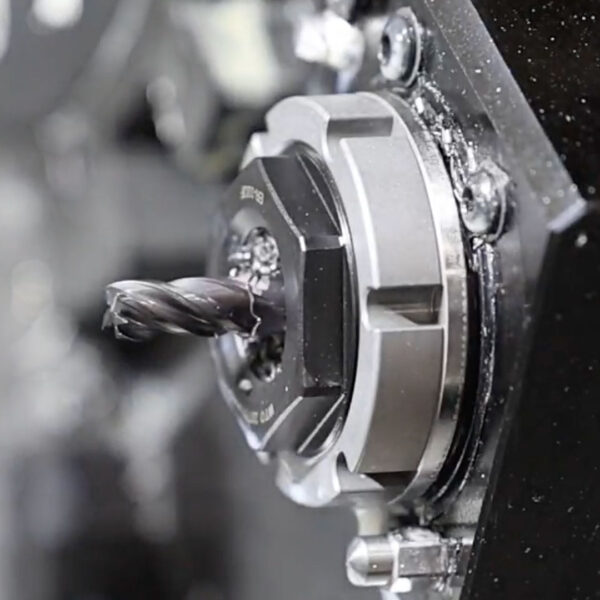

- Tight Tolerances: Our CNC processes routinely hold tolerances as tight as ±0.0001″.

- ISO 9001 Certified: Every part we produce is backed by documented quality systems.

- Controlled Goods Certification: Building toward defence-grade compliance.

- Prototyping to Production: Start small, scale fast with the same trusted partner.

- Fast Turnaround: Local production means quicker iterations and deliveries.

- Lot Traceability: For medical, aerospace, and critical component requirements.

Applications and Industries We Serve

- Aerospace and Defence: brackets, housings, instrument mounts, UAV components

- Medical and Life Sciences: lab equipment frames, surgical tool components, dental device parts

- Marine and Security: corrosion-resistant fittings, ruggedized mounts, structural supports

- Industrial and Energy: custom jigs, mechanical couplings, high-durability enclosures

FAQ

What is your typical lead times?

What materials can you work with?

Do you offer design assistance?

What quality standards do you follow?

Where does your tooling come from?

Testimonials

“From the moment I reached out with an inquiry, I was met with prompt and courteous responses that exceeded my expectations. What truly stood out to me was the level of personalization and attention to detail in every interaction. It was evident that the company prioritizes customer satisfaction and takes great pride in delivering a positive experience. Thanks to their outstanding customer service, I not only had my issue resolved in a timely manner but also felt valued and appreciated as a customer. I would highly recommend this company to anyone looking for top-notch service and support.”

Kevin Darakji, Design Engineer

EVDC

Recent Posts from Our Blog

The Importance of Draft and Radii in Effective Injection Molding Design

Why is Draft Important in Injection Molding Design? Applying draft and radii to a part is vital to a properly….Read More

How Does Coring Out and Ribbing Enhance Part Design Integrity?

How Does Coring Out and Ribbing Enhance Part Design Integrity? When designing parts for injection molding, maintaining proper wall thickness….Read More

Do Complex Rapid Injection Molding Designs Need to Be Simple?

Rapid injection molding requires that your part design should be as simple as possible, right? This is another false assumption….Read More

Ready to Start Your CNC Machining Project?

From a single prototype to full production, we’re ready to deliver parts that meet your performance, compliance, and schedule needs with the service you deserve.

Request a CNC Machining Quote